Technology

CNGmotive has the proprietary and exclusive ability to economically fill tenders in times similar to diesel. This factor allows CNGmotive the unique ability to offer the inherent advantages of CNG without the long held paradigm of extended filling times for CNG.

CNG Replaces Diesel Fuel in Locomotives

Introduction to the Industry

Major railroads in North America collectively burn approximately 5 BILLION gallons of diesel fuel annually principally for use in freight service diesel-electric locomotives. Railroads are classified by revenue and the largest are Class 1. CNGmotive’s commercial offers addresses the cost of railroading in North American at the apex of the challenge. The largest two cost factors routinely reported by Class 1 railroads are labor/HR cost and fuel cost. The price of oil at times has made fuel the #1 cost for railroads, reaching >20% of revenue in some instances.

Railroads have few commercial advantages in addition to cost of transport to the shipper. They very seldom are more timely, more reliable or more flexible than competitive modes of freight movement, such as highway trucks. This is most clearly revealed in the most competitive segment of traffic, standardized intermodal freight containers. The container is interoperable across truck and rail shipment. The competition to win intermodal business centers primarily on cost. Most shipping is done by third party logistics entities who guarantee to the ultimate customer (FEDEX, UPS, etc.) timely and reliable delivery for a fixed price. If the underlying mode of shipment is compromised, the freight container business can be diverted onto trucking very quickly. Very often the penalties for failure are extremely steep, loss of the business being a major one. To make money in intermodal operation and other segments of railroading, cost and reliability are paramount and thus low fuel cost is essential.

Significant attention is being paid to natural gas in North America as there are abundant supplies at very low cost in the short and long term. The conventional wisdom is that LNG is the only alternative for heavy duty users such as railroads and as such LNG pilot programs began a few years ago. CNGmotive has the ability to deliver compressed natural gas (CNG) with fill time and capacity performance of its LNG competitors, at a fraction of the cost.

Intellectual Property and Proprietary Advantages

CNGmotive, Inc. has exclusive rights to Intellectual Property which gives it the unique ability to economically provide Compressed Natural Gas in the form a locomotive can use it to displace the use of 60-75% of the diesel fuel normally consumed. Paramount in this scenario is the ability to design and deliver a fuel carrying rail vehicle to supply the locomotive(s) (a tender) and be able to refill the tender in cycle times similar the refueling of diesel tanks (<1hr) and operate in a safe and robust manner.

Despite very low diesel fuel prices now, the savings offered by CNGmotive to NA Class 1 railroads is approximately $1/gallon. CNGmotive bases its projections on a more conservative immediately addressable market of 3.5 billion gallons (highest intensity diesel fuel uses) and conservative 60% fuel replacement to scale the total Class 1 market at $2.1 Billion annual savings to the 7 Class 1’s even at the present low diesel fuel prices.

Exclusive and Proprietary IP to CNGmotive

Composite glass fiber tanks

Composite glass fiber tanks cost-comparable to steel w/ 40% of the weight and <50% of the cost of carbon fiber alternatives

Chilled filling process

Chill Fill ® process for CNG to full rated capacity in <45 minutes, at a fraction of the energy and CAPEX of alternative methods

CNG enabling

Multiple methods for dual-fuel and dedicated CNG enabling IP for Class 2 and Class 3 railroads, including switching and local operations

Technical Advantages

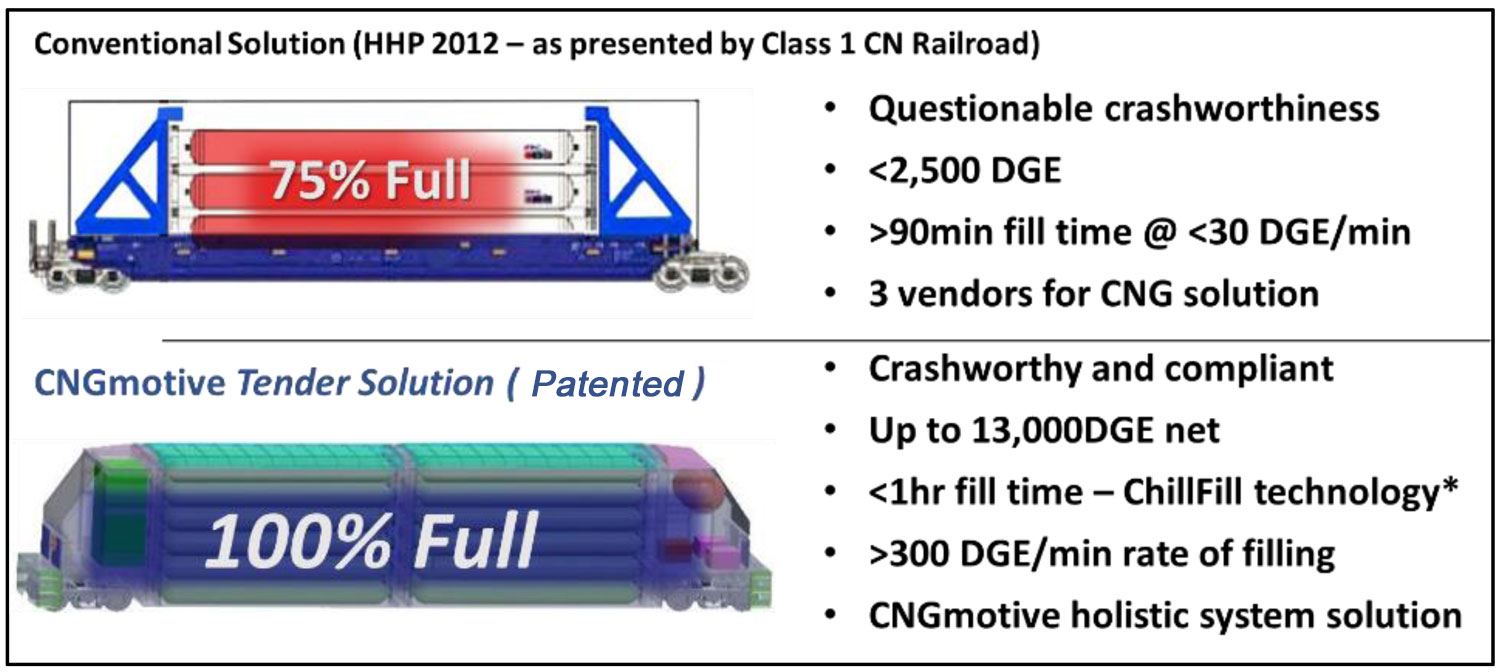

CNGmotive has the proprietary and exclusive ability to economically fill tenders in times similar to diesel. This factor allows CNGmotive the unique ability to offer the inherent advantages of CNG without the long held paradigm of extended filling times for CNG. Railroads had previously dismissed CNG in mainline operations due to the issues now solved by the CNGmotive exclusive technology and engineering achievements. CNGmotive’s >3yr market development experience in CNG for railroads makes it now technically obvious that its designs and processes enable CNG adoption by Class 1 RR’s in NA.

The two underpinning factors in being able to offer low cost CNG as a locomotive fuel are:

CNG Rapid Refuel

We offer the ability to refill very large storage vessels in a 40 minute fill time and a less than 1 hour total fill cycle with our Chill Fill ® process.

Excellent and safe design

An excellent and safe design for tenders using the pressure vessels and processes which will meet all safety and operational requirements.

Conventional wisdom held that filling pressure vessels was limited by physics to be a very slow process requiring many hours to accomplish. The patented Chill Fill ® technology has obliterated that long held belief. There is multiyear successful application of the Chill Fill ® technology in the oilfield and industrial virtual pipeline markets and CNGmotive is the sole licensee of this IP for locomotive fueling applications. Since the process has been used in multiple applications both smaller and soon to be applications much larger than tenders, there is little to no technical risk of failure to meet the performance of refilling as outlined. One of the founders is the principle inventor of Chill Fill ® and has founded a number of companies and applications of the IP outside the rail world.

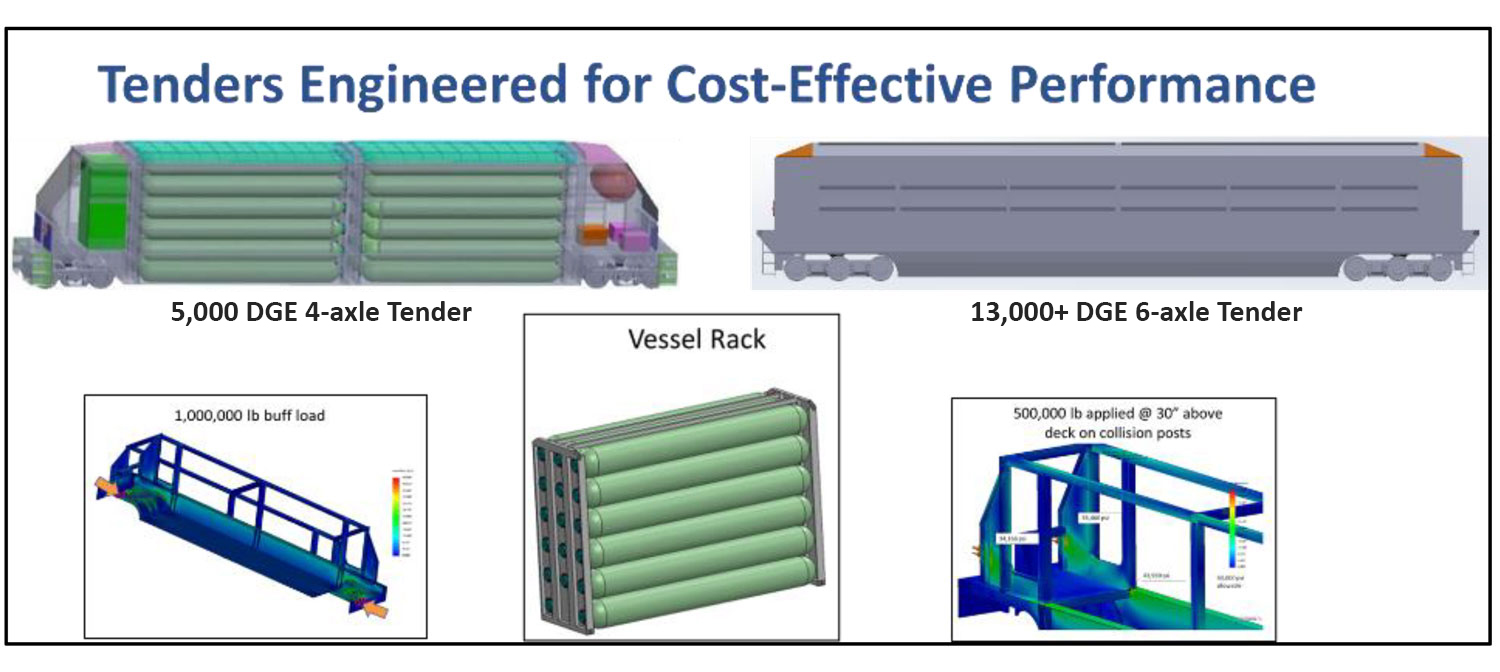

The second underpinning is a safe and crashworthy design for a tender which preserves the value of the fuel cost advantage to the end customer by being well adapted to the application. CNGmotive has executed two size classes of tenders already. These design efforts have been led by a founder, a former senior executive in the General Motors locomotive business and by the former key designer of General Motors locomotive vehicles. The output of this team are designs which far exceed the anticipated safety regulations and still provide the ultimate customer excellent interoperability and compatibility.

One of many additional advantages is compatibility with modern locomotive usages

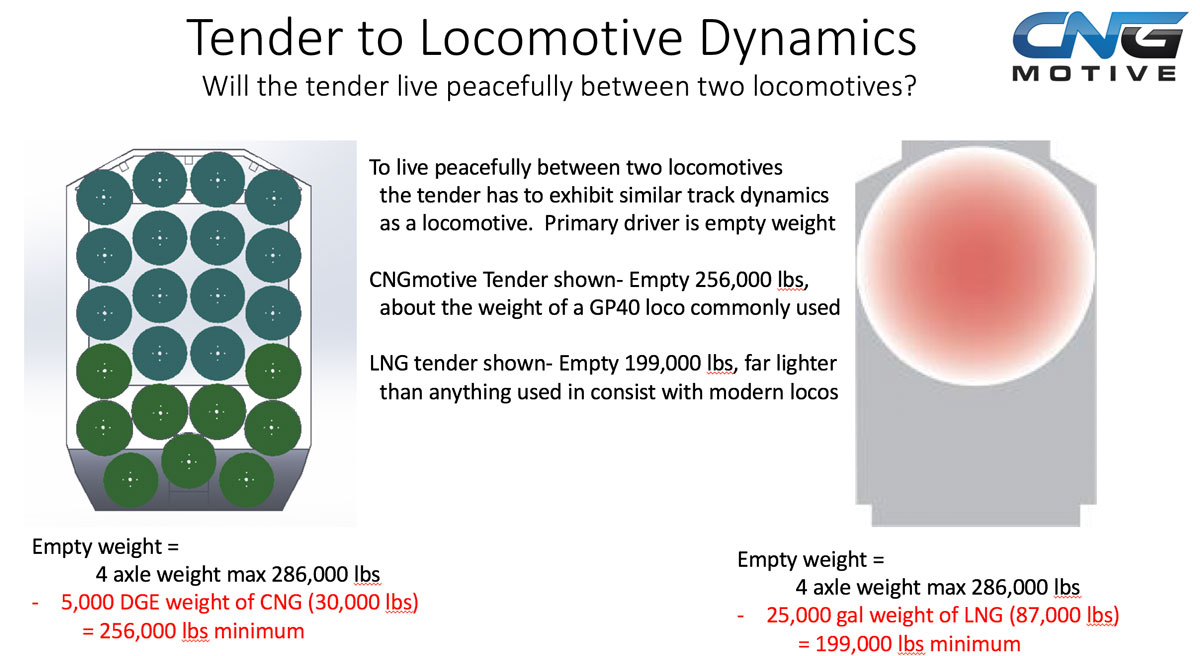

The effective use of tenders is most often envisioned as placement between two locomotives in consist. The term “in consist” is railroad speak for locomotives hooked together and being controled from a single cab on one of the units. This is a highly effective way for locomotives to be employed in multiples and is virtually certain to be the way locos are seen together at the head of a train or else where in the train or at the end of a train. In the CNGmotive team’s long experience with both tender design and locomotive design we have understood the requirements for a vehicle to operate safely and economically goes far beyond the safe and economic delivery of cng. One of the key elements of this “in consist” tender is to have the key track-train characteristics very similar to locomotives. Most commonly cited are vehicle weight and bogie configuration. The illustration below shows how the CNGmotive tender maintains appropriately heavy weight to be a stable consist partner to modern locomotives. Illustrated also is the typical situations for Liquified Natural Gas tenders which have an empty weight generally far below the minimum to assure stable operation “in consist”.

About CNGmotive

Our objective is to deliver the lowest cost clean and safe natural gas energy to heavy duty freight locomotives through the implementation of proprietary technology and decades of industry experience in locomotives.

Office

CNGmotive, Inc.

21016 80th Avenue, Suite 10

Frankfort, IL 60423

Phone

O: 779-333-7233